What Is Multi Courier Tracking for International Orders

Many customers are now in need of multi courier tracking services, which allow...

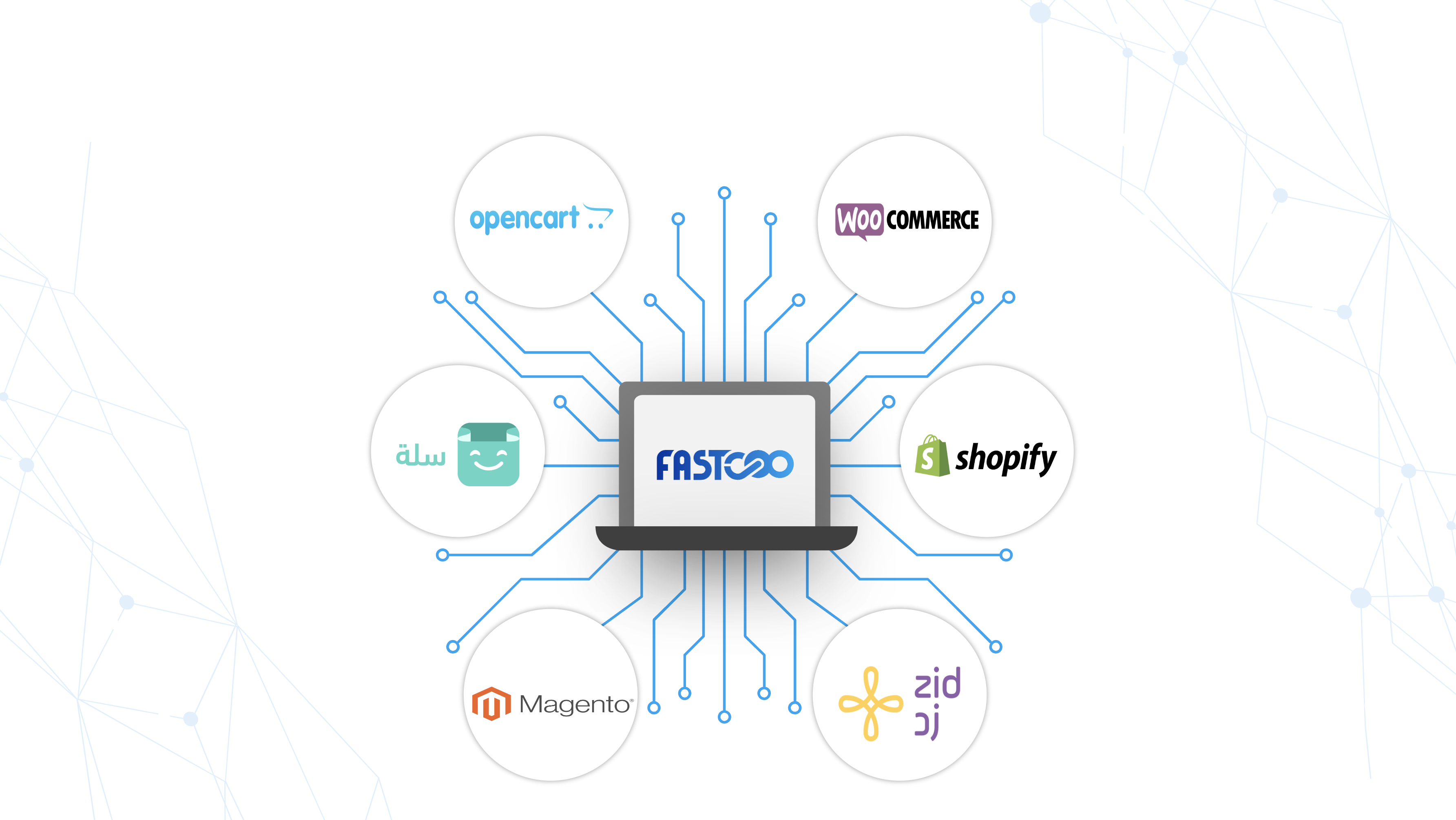

Fastcoo provides many TECH logistics services that will help you in your field of business.

Fastcoo provides many logistical services that will help you in your field of business

..

Many customers are now in need of multi courier tracking services, which allow...

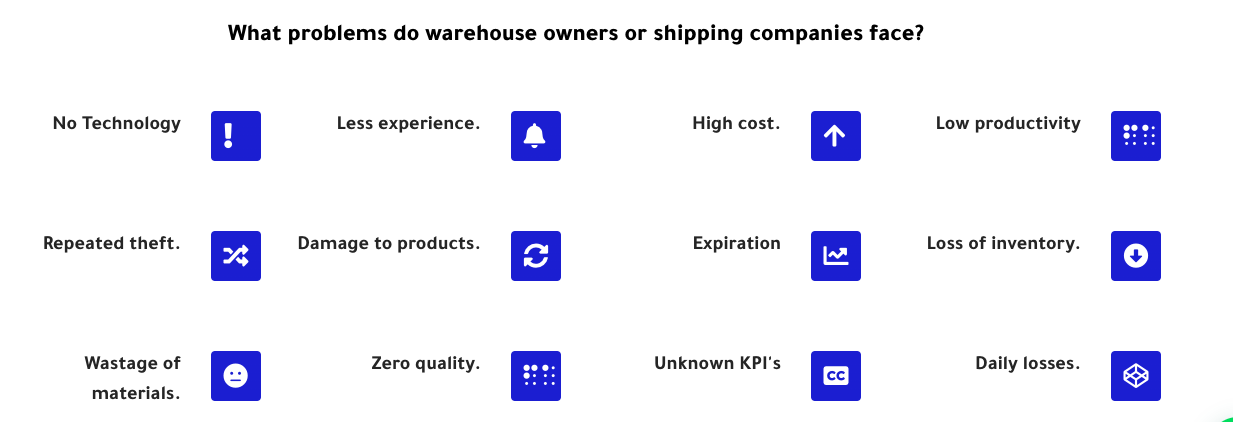

Cobots in Warehousing are very important in the supply chain, as they can help...

Many individuals and merchants are turning to eCommerce business, especially after...